We have been CNC machining services since 2008, more than 10 years. In a sense, the machinery manufacturing industry is in a fundamental position in the national industry. It is also a pillar industry of a country and can greatly affect the development of the national economy.

What is CNC machining?

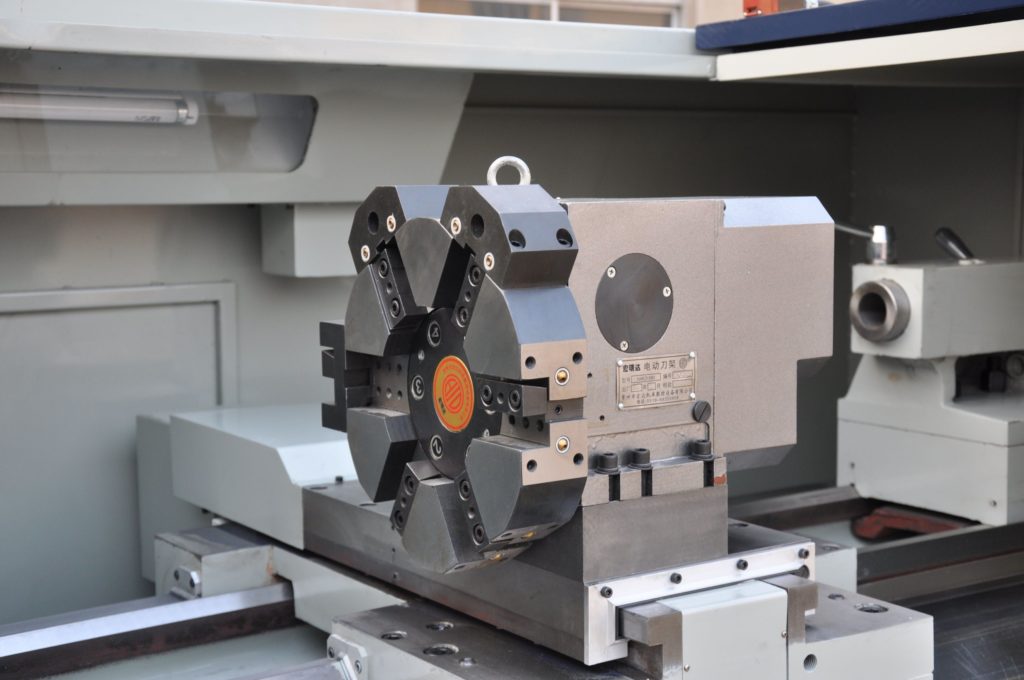

CNC machining is the process of removing scrap by advancing the workpiece by rotating the tool. This can change direction, cutter speed and pressure on one or more axes. CNC machining covers a variety of different operations and machines, from small single parts to large heavy-duty combined milling operations. It is one of the most commonly used processes for custom parts to exact tolerances.

Milling can be performed using various machine tools. The original type of machine used for milling was a milling machine (commonly called a milling machine). After the advent of computer numerical control (CNC) in the 1960s, the milling machine gradually developed into a CNC machining centre: the milling machine was enhanced by automatic tool changers, tool magazines or turntables, CNC functions, cooling systems, and housings. CNC machining centres are usually divided into vertical machining centres (VMC) or horizontal machining centres (HMC).

From the number of axes of CNC machining centres can be divided into multi-axis machining centres such as 3-axis machining centres, 4-axis machining centres, and 5-axis machining centres. The higher the number of axes, the secondary clamping and multi-angle machining can easily cause data deviation problem.

The situation of the downstream industry

With the rise of the downstream consumer electronics industry in recent years, 3C automation equipment has become the main engine driving the growth of the CNC machine tool industry. From the perspective of market size growth, the CAGR of the consumer electronics industry from 2010 to 2015 was 14.5%, which is 2 pct higher than the CNC machine tool industry.

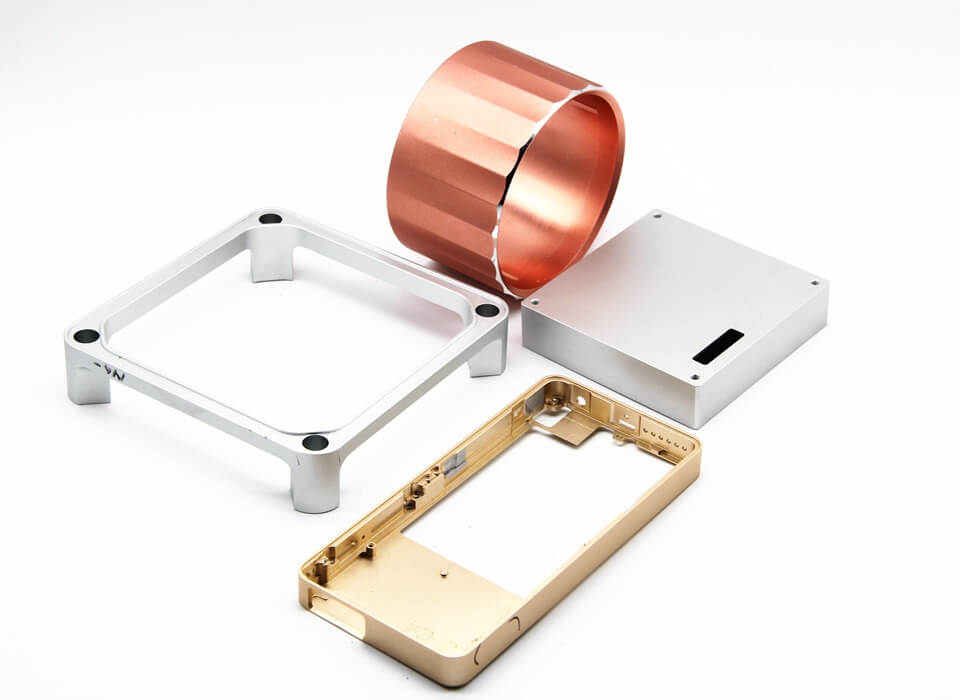

From the viewpoint of global shipments in 2016, mobile phones accounted for 73% of total 3C product shipments and were the primary source of demand for 3C automation equipment. Notebooks and PCs accounted for 21%. Global shipments of notebooks and PCs were 256 million units in 2016, and are supposed to be 250 million units by 2020. Although the shipments of notebooks and PCs have not changed much. Market demand mainly comes from new products brought by the internal hardware upgrades of products. Machine requirements. As the penetration rate of metal casings in the low-end and mid-range mobile phones continues to increase, there is still strong demand for metal CNCs: Compared with customers such as Apple and Samsung, the penetration rate of metal casings for domestic brand mobile phones remains low.

The case penetration rate is 90%, while domestic brand mobile phones are lower than 20%. In the future, a large number of domestic low-end mobile phones will enter the ranks of metal cases, and the demand for metal CNC equipment will continue to increase.

Benefiting from the design of the metal middle frame, the prosperity of CNC equipment is higher. The processing of the metal middle frame is more complicated than the previous aluminium-based cover plate, especially the stainless steel inner frame material is harder. The processing time is longer than the aluminium-based cover plate, which will stimulate more metal CNC equipment requirements.